linear density |

Product Features |

Resin Compatibility |

Applications |

2400、4800 |

Mainly for structural SMC product and general pigmentable SMC product |

UP、VE、PU |

Truck parts, water tanks, door sheet and electrical parts |

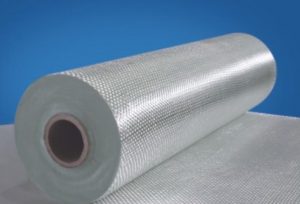

Material |

Yarn Cloth |

|

Chemical Formula |

E-Glass Fiber |

|

Surface Treatment |

Silane |

|

Weave |

Plain |

|

Thickness (mm) |

0.2 ±0.025 |

|

Construction |

WARP |

18 45 1/10 |

THRE Count/inch |

WEFT |

18 45 1/10 |

Weight |

158.8 ±10 |

|

Tensile Strength / WARP |

45.5 (kgf/in) |

|

Tensile Strength / Fill |

36.2 (kgf/in) |

|

Colour |

Natural |

|

Width |

1150 |

|

linear density |

Product Features |

Resin Compatibility |

Applications |

2400、4800 |

Mainly for structural SMC product and general pigmentable SMC product |

UP、VE、PU |

Truck parts, water tanks, door sheet and electrical parts |

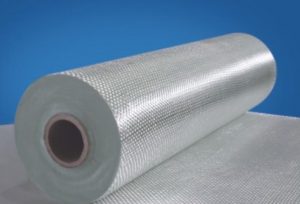

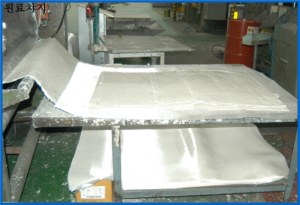

Material |

Yarn Cloth |

|

Chemical Formula |

E-Glass Fiber |

|

Surface Treatment |

Silane |

|

Weave |

Plain |

|

Thickness (mm) |

0.2 ±0.025 |

|

Construction |

WARP |

18 45 1/10 |

THRE Count/inch |

WEFT |

18 45 1/10 |

Weight |

158.8 ±10 |

|

Tensile Strength / WARP |

45.5 (kgf/in) |

|

Tensile Strength / Fill |

36.2 (kgf/in) |

|

Colour |

Natural |

|

Width |

1150 |

|

© All Rights Reserved.