· Sheet moulding compound (SMC) or sheet moulding composites is a ready to mould glass-fiber reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls or zig-zag packing weighing up to 1000 kg.

· SMC is both a process & reinforced composite material. This is manufactured by dispersing long strand (usually≤1 inch) of chopped fiber (commonly glass fiber or carbon fiber on a bath of thermoset resin (commonly polyester resin, vinyl ester or epoxy resin). The longer fiber in SMC result in better strength properties than standard bulk moulding compound (BMC) products.

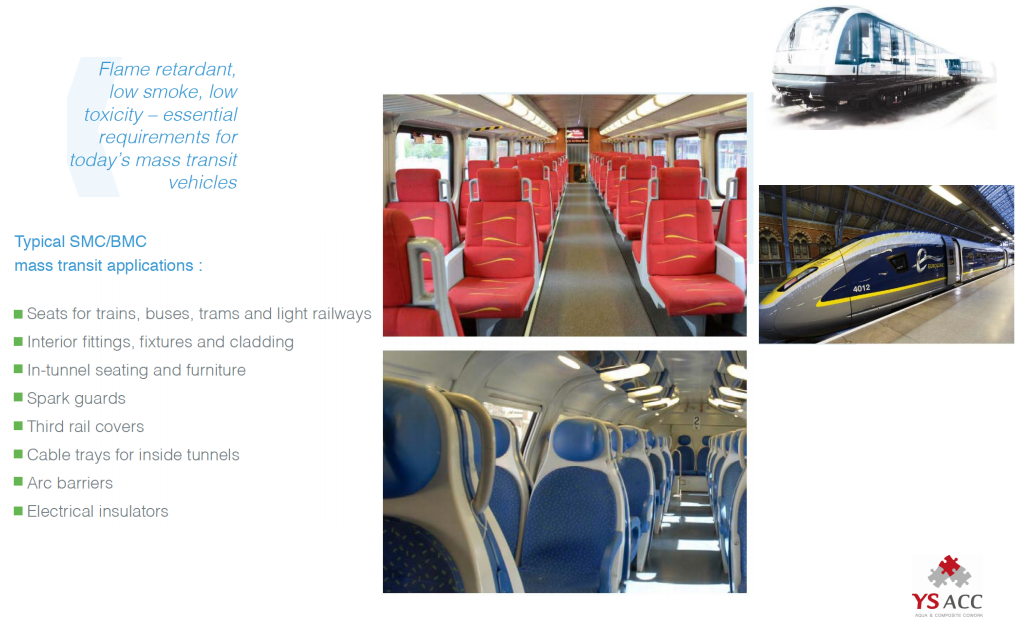

· Typical applications include demanding electrical applications, corrosion resistant needs, structural components at low cost, automotive, sanitary ware and transit.

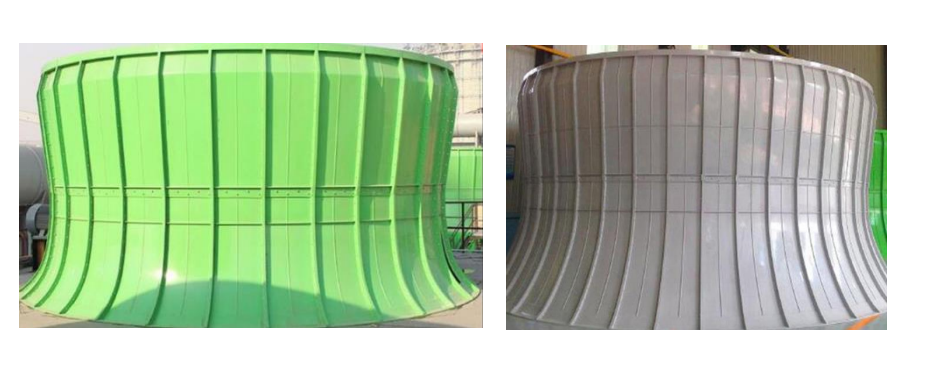

Corrosion Resistance Perhaps the prime reason for using SMC (Sheet Moulding Compound) is because of their inherent corrosion resistance

Weight Advantages Another very distinct advantage of SMC is its low weight-to-strength ratio. As a rule of thumb, for the same strength, SMC will weigh approximately one seventh as much as steel, and half as much as aluminum.

High Strength While not as important for corrosion-resistant equipment, high strength does play a major role in the design of products made from SMC for such applications as water tank, Manhole covers, Automotive parts, Electrical parts, etc.

Economy Often, a major advantage of SMC is its lower cost. When comparing materials for corrosion service, rubber lining, titanium, Monel, Hastelloy, Carpenter 20, and the exotic stainless materials are very frequently alternatives to SMC.

Flexibility Too many people overlook the versatility of SMC. It is best for many applications because you can do things with it that cannot be done economically with other materials. You can mold almost any configuration, or piece of equipment, for which you can build a temporary or permanent mold.

SMC is commonly packed in a cotton box with Zig-zag format. A single packing is up to 1000kg.

Store in a dry, cool area in room temperature. Keep them tightly closed to prevent contamination and evaporation after use.

GENERAL PROPERTIES |

||||

|

PROPERTY |

25% |

35% |

||

|

PHYSICAL |

|

|

|

|

|

|

|

1.7-1.9 |

1.7-1.9 |

|

|

MOLD SHRINKAGE |

|

0.15-0.2 |

0.1-0.15 |

|

|

GLASS CONTENT |

|

24-26 |

34-36 |

|

|

WATER ABSORPTION |

<0.2 |

<0.25 |

||

|

MECHANICAL |

|

– |

– |

|

|

TENSILE STRENGTH |

|

750 |

1100 |

|

|

FLEXURAL STRENGTH |

1600 |

2200 |

||

|

COMPRESIVE STRENGTH |

1800 |

2500 |

||

|

IMPACT STRENGTH |

|

50 |

100 |

|

|

ELECTRICAL |

|

– |

– |

|

|

VOLUME RESISTIVITY |

14 |

14 |

||

|

SURFACE RESISTIVITY |

12 |

12 |

||

|

TRACKING INDEX |

|

+800 |

+800 |

|

|

DIELECTRIC STRENGTH |

12 |

11 |

||

|

ARC RESISTANCE |

|

+180 |

+180 |

|

|

THERMAL |

|

|

||

|

|

|

+145 |

+145 |

|

|

FLAMMIBILITY |

V0 |

V0 |

||

|

MOLDING CONDITION |

– |

– |

||

|

PRODUCT THICKNESS |

3 to 20 |

3 to 20 |

||

|

MOLD TEMPERATURE |

130 to 160 |

140 to 170 |

||

|

MOLDING PRESSURE |

30 to 100 |

30 to 100 |

||

|

CURING TIME |

|

30 to 50 |

30 to 50 |

|

© All Rights Reserved.