WETTING & DISPERSING AGENT

DESCRIPTION

Wetting and dispersing additive for SMC/BMC and pultrusion to homogenize and stabilize

the system, and to increase the colour homogeneity in moulding compounds.

Improved fibre wetting and therefore optimized properties. Anti-separation additive.

COMPOSITION

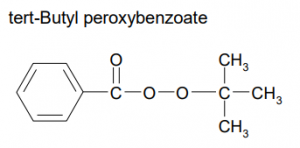

Solution of a high molecular weight block copolymer with pigment affinic groups

TYPICAL PROPERTIES

The values indicated in this data sheet describe typical properties and do not

constitute specification limits.

· Amine value: 11 mg KOH/g

· Density (20 °C): 1.02 g/ml

· Refractive index (20 °C): 1.438

· Non-volatile matter (20 min., 150 °C): 30%

· Flash point: 38 °C

APPLICATION

SMC, BMC, Pultrusion

Special Features and Benefits Additive to prevent phase separation in PS-UP filled moulding

compounds. It improves the pigment dispersion and pigment stability in LS

systems. In HMC, BYK-W 972 optimizes the fibre wetting and therefore the

mechanical properties.

RECOMMENDED USAGE

0.5-1% additive (as supplied) based upon the resin, to prevent phase separation.

0.5-1% additive (as supplied) based upon the fibre content, for fibre wetting.

30-140% additive (as supplied) based on the pigment, to stabilize organic pigments and carbon blacks.